color case hardening temperature

Im guessing i could just send the. A lot of really old model rifles have color case hardening these days but i love to see handguns that have this finish on them.

Kasenit and similar compounds are a lot easier to use and you can just use a torch.

. Working temperature ranges from 1200 to 1600 degrees f. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps. Temperatures from 1250 to 1500 F and heating times of from 1 to 5 hours.

You have to watch the temperature more closely with color case hardening or the colors wont come out well. We are located in northeast Iowa right in the heart of whitetail pheasant and trout country. It is heated to somewhere around 1200 to 1400 degrees and then quenched.

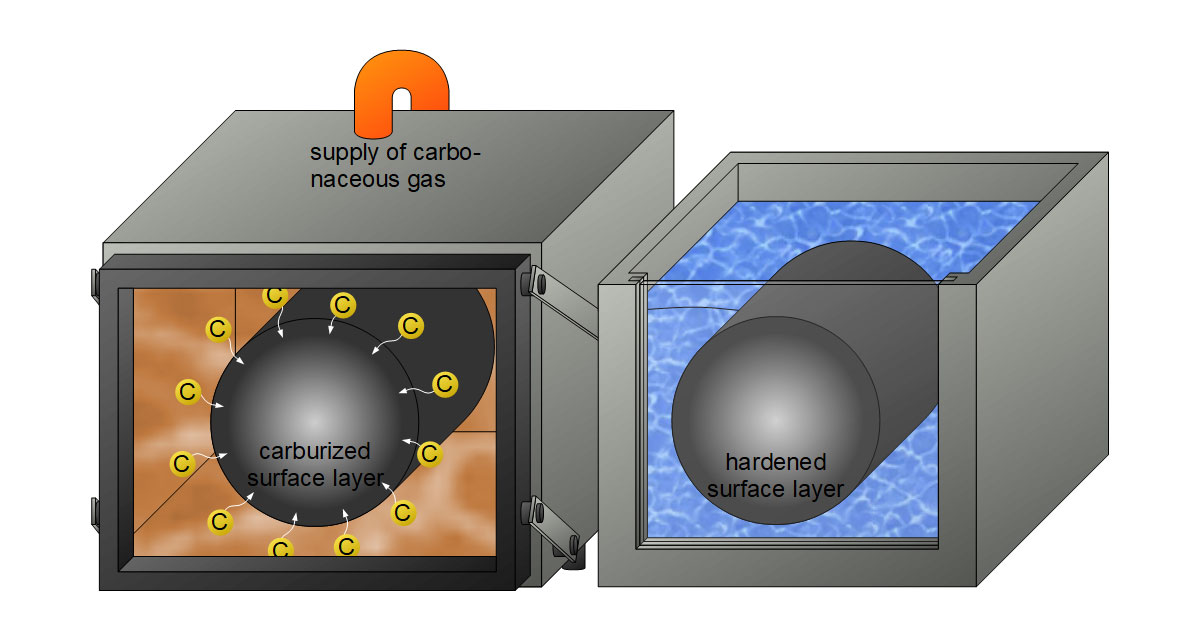

Originally this process used. To achieve these results we use the traditional method of packing the component into a steel crucible together with a generous amount of charred bone wood and leather then heating the entire unit to a temperature of 1400 degrees F for two hours or more. Then that package is placed into a high temperature furnace.

Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. The metal is heated to 1400 degrees and must be moved around at a similar temperature which creates a significant risk of fire and serious burns. I have been successful color hardening by placing the parts in a capped 4 inch pipe in a charcoal fire for several hours then quenching in cold water.

Most of the newer receivers made today are made of pre-heat treated steel. Our color case is done using a mixture of bone and wood charcoal. We specialize in traditional wood and bone charcoal color case hardening.

Working at low temps gives us the ability to bring you the colors you deserve without double heat treating your steel. But then I have been unsuccessful using the same method. The resulting shell of hardened metal can be.

Contact Brownells and ask for their instructions for color case hardening. Color Case Hardening is a process for the surface hardening of steel which results in a decorative mottled-color finish. Although that could happen if the proper temperature controls and quenching are employed in conjunction with the carburizing.

It would not necessarily by itself create a hardened case or outer layer. First we prepare the parts by doing a complete disassembly and clean the. Color Case Hardening Services.

If you dont wear appropriate safety gear you should stay away from this project. One of the best-known men for color case hardening in the Birmingham quarter was Bill Woodward McKay Brown said. Bone charcoal case hardening takes a good deal of time with parts needing to be carefully packed into a bath of charcoal and heated carefully up to the neighborhood of 1300- to 1400-degrees Fahrenheit.

Lynn Huntsville AL Comment. The same colors also develop on stainless steels and titanium at different temperatures and times. Canoe Creek Case Hardening.

Faint yellow starts about 300 F longer times give more color development of color. We share your passion for the outdoors and for beautiful case hardened guns. Its brought up to a high temperture and held there until the carbon migrates from the charcoal into the outer.

Dont go over 1350 F. Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade steel. You must have a heat treating oven or something similar to be sure.

These colors were developed during tempering heat-treatment after case hardening. Case Hardening on a 2nd Gen Colt. Next remember color case hardening is a hardening process and when you harden critical gun.

Then that package is placed into a high temperature furnace. Recommendations to highly polish all parts and recommendations to not ex - ceed 240 grit. We keep our temperatures below hardening temperatures.

As far as the color case hardening was concerned those pretty mottled. Let me be blunt. The process of bone charcoal color case hardening involves taking the part and packing it in a combination of wood charcoal and bone charcoal in a stainless steel crucible.

Starting with yellow then blue and purple in a continuous transition. By Shameless Womanizer 57929 October 2 2011 In. Bonewood charcoal ratios from 11 to 120.

How To Do Color Case Hardening The Hobby Machinist

American Handgunner When You Re Hot American Handgunner

Guns Magazine Case Hardening Redux Guns Magazine

American Handgunner When You Re Hot American Handgunner

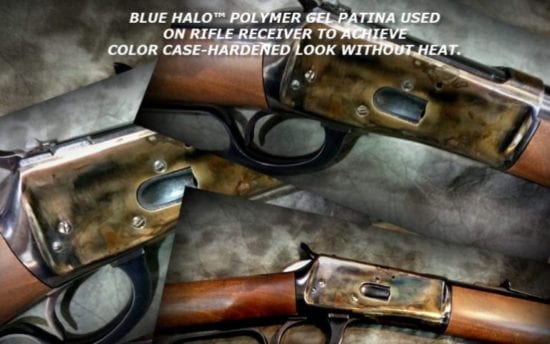

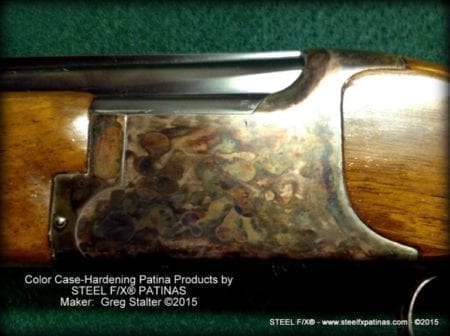

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Color Case Hardening Shooting Sportsman Magazine

Color Case Hardening Patina Kit

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration

The History Of Case Hardening And Its Processes Double Stone Steel

Color Case Hardening Turnbull Restoration

American Handgunner When You Re Hot American Handgunner

How To Color Case Harden Presented By Larry Potterfield Midwayusa Gunsmithing Youtube

Color Case Hardening Turnbull Restoration

Color Case Hardening Turnbull Restoration